[% INCLUDE header.us3/

title = 'UltraScan III PCSA Analysis Control'

%]

UltraScan Fit Controls for PCSA:

The parameters of this dialog define and control an analysis run

to find the set of solutes that best fits experimental data.

Each analysis run proceeds over a defined set of curves in s and f/f0

space. The single analysis pass produces the model whose associated

simulation differs the least from the experimental data, as determined

by its RMSD value. Time-invariant and/or radially-invariant noise(s) may

also be computed. The curves in a set cover a specified s and f/f0 range

and vary according to a specified increment or count. Each model has

a specified number of input solute points along its curve.

After an initial pass in which all the specified model curves are

evaluated, the results are sorted by fitness (least RMSD). The best model

then becomes the starting point for a second pass that utilizes

Levenberg-Marquardt to refine the model. The result of that second pass

is inserted as the final best model.

For a straight line type, a specified variation count is given.

Lines cover the full s range, with end points along the f/f0 range

varying the specified number of times. Each implied starting point

connects with each of the possible end points. So the square of the implied

number of f/f0 end points is the number of models analyzed. If the type

is Horizontal Line, the f/f0 value is the same for start and end points,

so the number of models is the variations count itself (not its square).

For sigmoid types, a variation count is directly specified. The curves

cover the full s and f/f0 ranges, with "par1" and "par2" values each varying

the specified number of times, yielding a number of test models equal to

the square of that count. The par1 value changes logarithmically from 0.001

to 0.5; and par2 changes linearly from 0.0 to 1.0.

Process:

-

Set the Curve Type: First, specify the type of curve you

expect the species to follow. Choices are:

- Straight Line

- Increasing Sigmoid

- Decreasing Sigmoid

- Horizontal Line [ C(s) ]

-

Define the Ranges: Next, define the s and f/f0 ranges; and

directly (sigmoids) or indirectly (lines) give the number of

variations in each dimension.

-

Specify Resolution Points: Specify how many solute points

exist on each curve.

-

Set Threads: Next, after control values are set, define

a number of threads that is appropriate to the complexity of the run

and the number of processors or cores available on your machine.

-

Start the Fit: Begin the fit analysis by clicking

"Start Fit".

-

Display and Save Results: After simulation, a variety of

options are available for displaying simulation results, residuals,

and distributions. Report text files and graphics plot files can

also be generated.

-

Regularize: If you wish to perform Tikhonov Regularization,

you can set a Regularization Parameter (Alpha) or determine a good

parameter value by clicking "Perform Regularization Scan". When you

have a reasonable Alpha, click on Regularize Current Model.

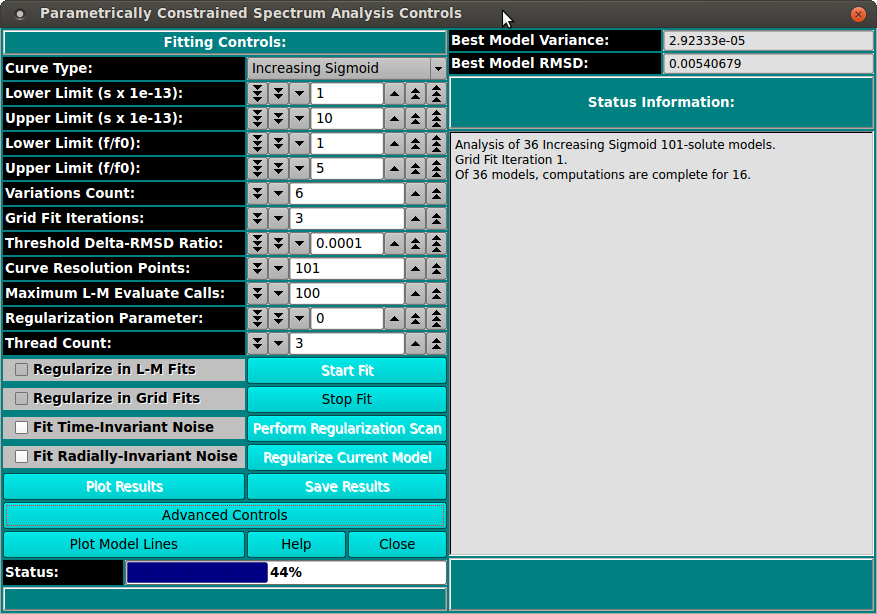

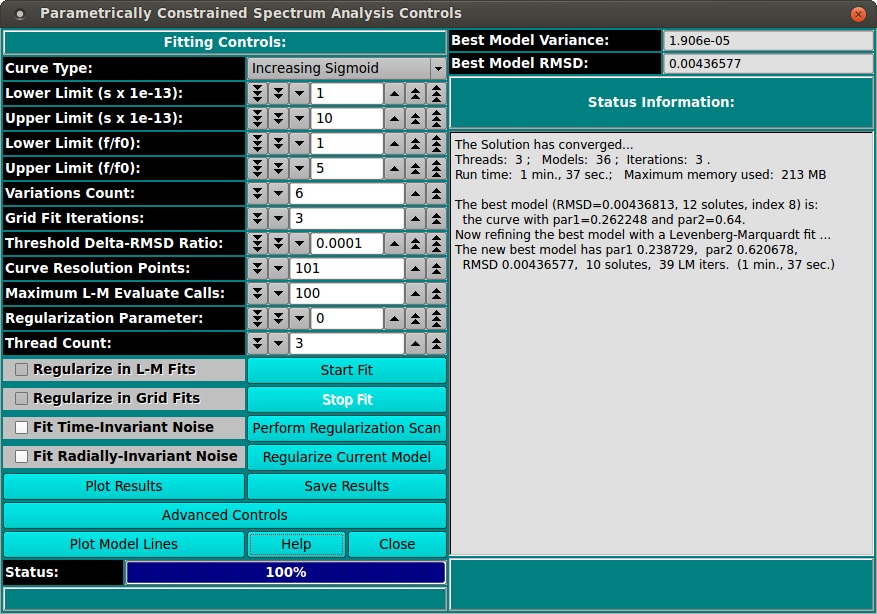

Sample Control Dialogs:

Control dialog parameters differ slightly in interpretation, based on

whether the curve type is a line or a sigmoid. If straight line is

specified, the curve variation count gives the number of start and end point

f/f0 variations. If horizontal line is specified, curve variations gives

the total models, since start and end points always have the same f/f0

value.

If one of the sigmoid types is specified, the specified number of

variations is in both the par1 and par2 values of the sigmoid function

y = y_start + y_diff * 0.5 * erf( ( x - par2 )

/ sqrt( 2.0 * par1 ) ) + 0.5

.

Functions:

-

Curve Type: Select from the list of types; either a line

or one of the sigmoid types.

-

Lower Limit (s x 1e-13): Set a lower limit of sedimentation

coefficient values to scan.

-

Upper Limit (s): Set an upper limit of sedimentation

coefficient values to scan.

-

Lower Limit (f/f0): Set a lower limit of frictional

ratio values to scan.

-

Upper Limit (f/f0): Set an upper limit of frictional

ratio values to scan.

-

Variations Count: Specify the number of curve variations in

each direction to form the models. Usually, the square of this value

is the number of models to analyze. The number of variations

is applied to each of "par1" and "par2" in the sigmoid computations.

In the Horizontal Line case, this value is the number of models.

-

Grid Fit Iterations: Specify the number of iterations of

fixed grid fits to perform. Each iteration after the first starts

with a range of par1 and par2 values or f/f0 values that is

refined from the best models of the previous iteration.

-

Threshold Delta-RMSD Ratio: Specify the ratio of the delta

in RMSD to previous iteration RMSD that is the threshold below

which the iterative scan is taken to have converged.

-

Curve Resolution Points: Specify the number of points to

generate for each test line. This is the number of solute points

that each model will have.

-

Maximum L-M Evaluate Calls: Specify the maximum number of

Levenberg-Marquardt evaluate calls to allow. The default value of

100 is almost always sufficient for L-M to converge. This value is

used to insure that a run-away condition will not occur.

Additionally, a value of "0" may be specified to suppress L-M and

use the final fixed grid best model as the overall best model.

-

Thread Count: Specify by counter the number of threads

to use for computations. This value is the total number of worker

threads used at one time. The master thread generally has little

work to do during computations, so the value may be set to your

machine's total processors or cores.

-

Start Fit Click to begin the fit analysis. The analysis will

proceed through fixed curve analysis followed by Levenberg-Marquardt

refinement, resulting in either a final model or the base model

from which regularization may proceed.

-

Stop Fit If something seems wrong with the progress of

analysis or if you realize you have parameterized incorrectly,

click this button to abort the fit run.

-

Perform Regularization Scan Once fit analysis is complete,

you may optionally click here to bring up a

Regularization Parameter Scan dialog

that sets the best value for Regularization Parameter.

-

Regularize Current Model Any time you set the Regularization

Parameter, either manually or through scan, you may then compute a

final model, using that parameter, by clicking here. Note that if

the parameter is set to zero, the button here is relabeled to

"Unregularize Current Model".

-

Regularize in L-M Fits This box should normally remain

unchecked, but you may check it in order to test regularization

during the Levenberg-Marquardt stage of model fitting.

-

Regularize in Fixed Fits This box should normally remain

unchecked, but you may check it in order to test regularization

during both the fixed-curves and L-M stages of model fitting.

-

Fit Time-Invariant Noise Check this box if you want to

calculate time-invariant noise.

-

Fit Radially-Invariant Noise Check this box if you want to

calculate radially-invariant noise.

-

Plot Results Open 3-D and Residual plot dialogs to display

final results.

-

Save Results: Save final model(s) and any noises generated.

Also output report and plot image files.

-

Plot Model Lines Click on this button to open a dialog showing

the Model Lines specified (such as

Sigmoid Models). Note that

the dialog is automatically opened upon analysis completion. But this

button can be used to re-display completed model lines if the dialog

has been closed by the user. The dialogs after analysis include

color-coded illustrations of best and near-best models:

Fitted Models.

-

Help Display this and other documentation.

-

Close Close all windows and exit.

-

Status: A progress bar showing activity progress within

each iteration pass.

-

Best Model Variance: The minimum variance value for models

thus far computed is continually updated.

-

Best Model RMSD: Simularly, the minimum RMSD value for

models thus far computed is continually updated. Note that at

completion of all model computations, this box and the one above

will hold values for the final best model, which might not be a

minimum (when regularizing, for example).

-

Status Information: The text box here is continually updated

with summaries of analysis activity and results.

Notes on Fit Stages and Regularization:

-

During all model fitting runs, at least two fit stages occur:

-

Fixed Stage: The models following fixed curves that were

defined are evaluated and results ordered by best fitness

(least RMSD).

-

LM Stage: The best model from the previous stage forms

the starting point for a Levenberg-Marquardt fit sequence that

results in a refined model being found. This refined model gets

inserted at the top of the ordered models list.

-

If you wish to apply Tikhonov regularization in order to smooth

concentration peaks in the final model, up to two additional stages

may occur:

-

Scan Stage: Starting with the best model from the LM

stage, a range of Regularization Parameter (Alpha) values is

tested in a separate dialog to derive an optimal Alpha.

-

Final Stage: The result of the LM stage is used as a

starting point for one final model computation, this time using

a given Alpha.

-

Where regularization is to be employed, then, the two most common

run sequences are:

-

Fixed+LM+Scan+Final -- where the optimal Alpha is

unknown and needs to be determined, then applied.

-

Fixed+LM+Final -- where the optimal Alpha is already

known or was determined in a previous sequence. This sequence

may be employed after a ...Scan... sequence that used moderate

Variations Count and Curve Resolution Points for speed. Those

Count and Points values may now be increased for accuracy

and this Fixed+LM+Final sequence performed.

-

Note that clicking the Start Scan button really initiates

a Fixed+LM+Scan sequence. When it completes, clicking on the

Final Fit button results in the Final stage being performed.

-

Note that where regularization is not to be employed (Alpha=0),

the only run sequences that will be used is:

Fixed+LM -- where the final LM model is the desired

overall final model.

[% INCLUDE footer.us3 %]

Manual

Manual

Manual

Manual